Look up “fan belt” in any modern automotive dictionary, and you’ll typically find a definition that reads, “An endless belt used to transmit power from a crankshaft-driven pulley to a pulley driving the fan, alternator, or other engine accessory. It is usually V-shaped in cross section, with the point of the vee fitting into a groove in the pulley”. Even though cooling fans on most modern vehicles are driven by electric motors instead of actual belts, the term fan belt is still incorrectly used as a blanket expression to describe any single accessory belt that may be used to drive a water pump, alternator, power steering pump, or other items. Why?

Look up “fan belt” in any modern automotive dictionary, and you’ll typically find a definition that reads, “An endless belt used to transmit power from a crankshaft-driven pulley to a pulley driving the fan, alternator, or other engine accessory. It is usually V-shaped in cross section, with the point of the vee fitting into a groove in the pulley”. Even though cooling fans on most modern vehicles are driven by electric motors instead of actual belts, the term fan belt is still incorrectly used as a blanket expression to describe any single accessory belt that may be used to drive a water pump, alternator, power steering pump, or other items. Why?

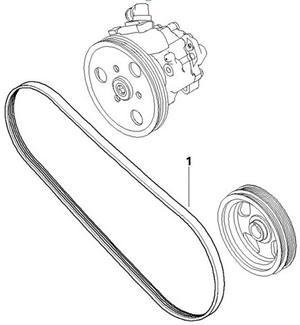

The term “fan belt” is still incorrectly used as a blanket expression to describe any single accessory belt (shown in this photo) that may be used to drive a water pump, alternator, power steering pump, or other items.

In order to pull cooling air through a vehicle’s radiator, a cooling fan (or fans) need to be located at the front of the vehicle just behind the radiator. Traditional rear-wheel-drive vehicles with longitudinally-mounted engines had crankshaft pulley wheels right there at the front of the car, and they were convenient sources of power for cooling fans. Since the fan belt tended to be the biggest and most noticeable one on the vehicle, the expression became universal for all other belts that looked similar – no matter what function they performed. Many original engine layouts also used that fan belt to spin water pump and alternator pulleys, causing the expression to become even more cemented in people’s minds.

However, as vehicles with front-wheel-drive and sideways-mounted engines grew in popularity, the “front” of the engine was no longer at the front of the vehicle where the cooling fan was.

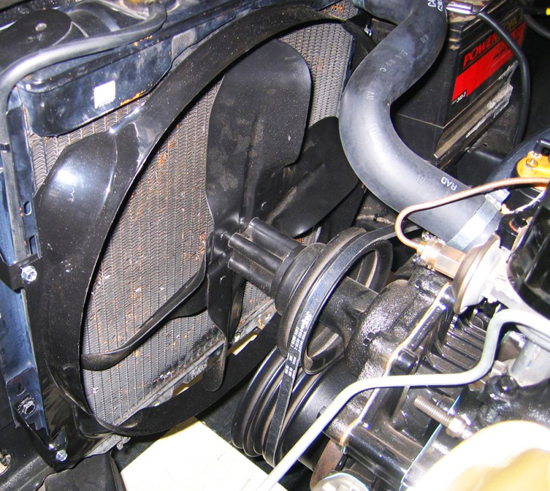

Shown in this picture of a 1966 Ford Mustang engine bay is an actual “fan belt” used to drive a cooling fan. Until recent decades, this was the traditional setup on vehicles with longitudinally-mounted engines.

As vehicles with front-wheel-drive and sideways-mounted engines grew in popularity, the front of the engine was no longer at the front of the vehicle where the cooling fan was. Belts could no longer be used, and fans with electric motors were perfected. Because of their greater energy efficiency, they’ve made belt-driven fans obsolete in virtually all automotive applications today.

Engineers perfected electric motors, temperature sensors, and related computers to get the job done, and fan belts were no longer necessary. Because cooling fans don’t always need to be running at steady cruising speeds, electric motors which can shut off proved more energy efficient than direct drive belts which are always connected. Since electric cooling fans are used even in modern vehicles with traditional longitudinally-mounted engines, the term fan belt has become virtually obsolete. A more fitting term to use when searching for a replacement single belt of any kind would be accessory belt or V-belt.

Because belts are subject to constant rotation, load, and heat, they are constructed in a similar fashion as tires. An outer layer of rubber surrounds internal steel and cord reinforcements to minimize stretching and maximize strength when grip is needed under load.

ACCESSORY BELTS

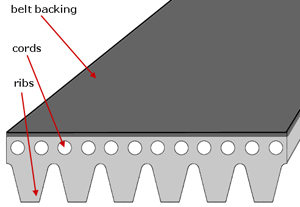

The inner construction of a typical reinforced rubber accessory belt. Because of a shape that tapers downward at the bottom, these are known as “V belts”. While this belt is not grooved along the bottom, most belts are.

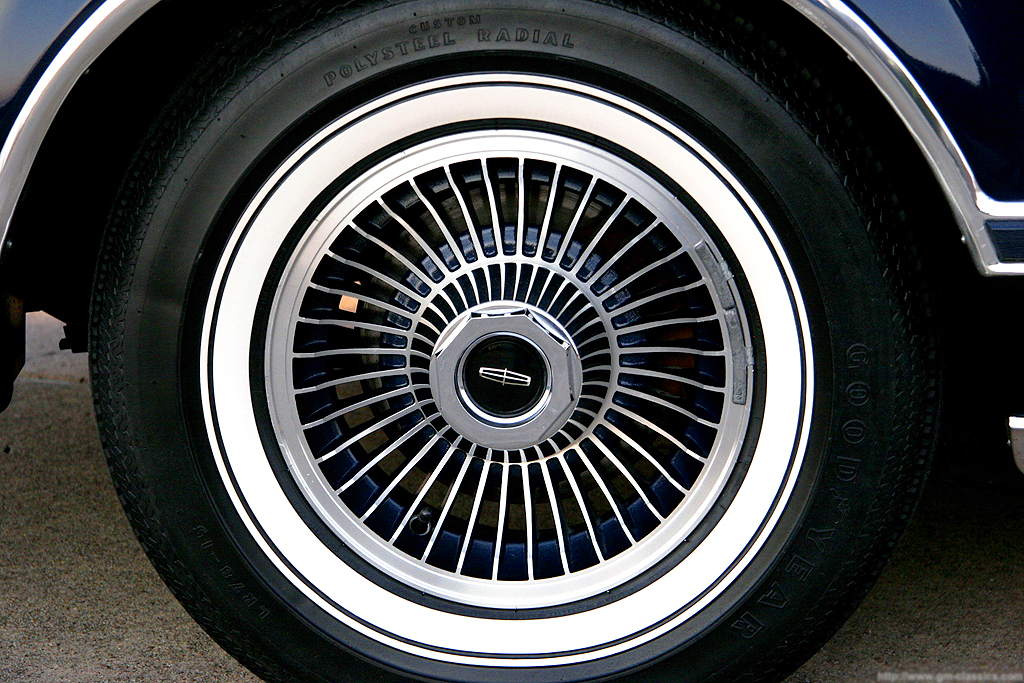

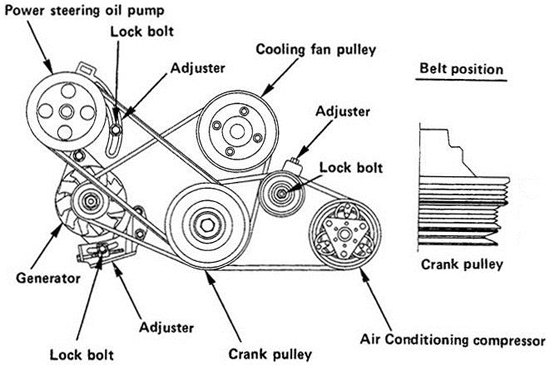

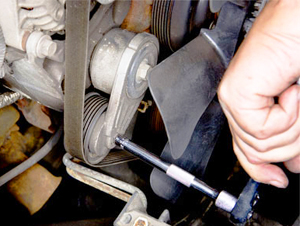

Automotive accessory belts mounted visibly outside the engine are also known as “V-belts” because their trapezoidal shape tapers from wide to narrow as it forms a V point near the bottom. The underside surface of the belt features endless parallel ridges designed to slot into mating grooves on the pulley wheel (known as sheaves) to prevent sideways slippage. As load pressures increase on this type of V-belt, rubber grooves wedge themselves further into the pulley sheaves and friction provides the necessary grip. Tension on individual accessory belts is controlled manually by tightening an adjuster to change the position of an idler pulley wheel, or by adjusting slotted mounting brackets that move accessories such as an alternator or a/c compressor by a fraction of an inch.

This photo shows an engine equipped with three separate accessory belts. One is for the cooling fan, another drives the a/c compressor and alternator, and the third drives the power steering pump. Tension on these belts is controlled manually by tightening an adjuster connected to an idler pulley wheel or by adjusting slotted mounting brackets for accessories (seen here on the alternator and a/c compressor

Because accessory drive belts are subject to constant rotation, load, and heat, they are constructed in a similar fashion as tires. An outer layer of rubber surrounds internal steel and cord reinforcements to minimize stretching and maximize strength when grip is needed under load. Like most exterior accessory belts, this one is equipped with parallel grooves on the underside of the belt surface.

These design benefits serve to make the Vee one of the most effective belt solutions because it needs less width and less tensioning than flat belts or other styles. Their ability to provide a small degree of slippage when needed makes them a good match for accessories that shut on and off by the use of a clutch, such as air conditioner compressors and older style radiator cooling fans. While belts of this type may or may not have multiple grooves, they are used for power steering pumps, alternators, auxiliary air pumps, and other accessories mounted outside the engine. Some vehicle manufacturers may use a separate belt for each accessory, and others may set up their pulley wheels with only a couple of belts hooked to multiple pulley wheels.

SERPENTINE BELTS

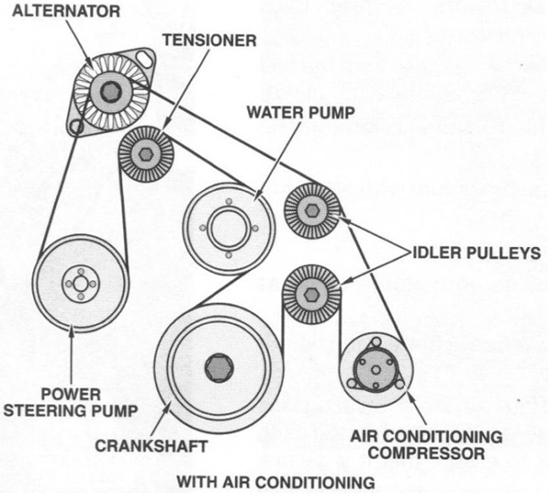

A serpentine accessory belt is simply a longer, endless belt constructed in the same fashion as a single accessory belt. As this picture illustrates, a serpentine belt will typically power all externally mounted accessories – even water pumps. Unlike individual belts, tightness on serpentine belts is provided by an idler pulley(s) under constant pressure from a heavy-duty spring loaded tensioner.

Visible in this photo is a spring-loaded serpentine belt tensioner. This type of tensioner never needs adjustment and will release its tension when force is placed against the idler pulley using proper hand tools – if the belt needs to be removed or replaced

A serpentine belt is simply a longer, endless belt constructed in the same fashion as an accessory belt. Instead of being specific to a single accessory, a serpentine belt is designed to wind around multiple pulley wheels – powering a vehicle’s alternator, air conditioning compressor, power steering pump, and even the vehicle’s water pump or cooling fan. One or both sides of a serpentine belt may be designed to provide friction. Freewheeling “idler pulley” wheels are positioned in various locations in order to reroute the belt in the direction of the next accessory.

Unlike individual belts, tightness on serpentine belts is provided by an idler pulley wheel that’s under constant pressure from a heavy-duty spring-loaded tensioner. A serpentine belt tensioner never needs adjustment, and will release its tension when force is placed against it using proper hand tools if the belt needs to be removed or replaced.

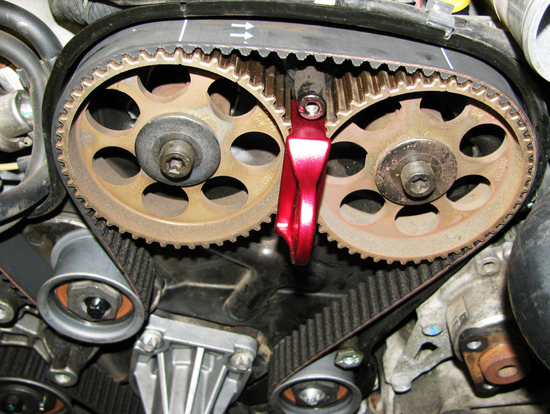

TIMING BELTS

Timing belts should not be confused with accessory belts. Unlike fan belts, serpentine belts, or any auxiliary belts that run accessories mounted on the outside of the engine, timing belts are encased inside the engine. They feature flatter construction with toothed grooves running across the bottom that mate with camshaft drive gears. A spring-loaded pulley provides constant tension to ensure this type of belt remains slip-proof so it can maintain a fixed speed necessary for the exact precision of camshaft timing. Belts that power superchargers usually feature this same toothed design and setup. Unlike friction belts, toothed belts (also known as notched or cog style belts) cannot be used on applications where slippage is needed for clutches that activate and deactivate.