Wheel bearings are as old and important as the wheel itself thanks to their ability to allow free rotation without damaging effects of friction and wear. In this article, we’ll define and discuss the individual components that make up a bearing assembly so that you can be more informed when looking for replacement wheel bearings, hubs, seals, and components. We’ll also cover the differences between “wheel bearings” or “axle bearings” mounted at the wheel itself along with “axle shaft bearings” located further inboard along axle shafts. “Bearings” are actually the small round pieces that spin within a bearing assembly. Even though bearings come in a variety of shapes, they all serve the same basic purpose.

TYPES OF BEARINGS

Ball bearings – These are perfectly round metal balls. While they’re used in some automotive bearing assemblies, they are more commonly found in skateboards, electric motors, and household machinery. Because their spherical shape allows them to spin in any direction, they can handle both radial loads (weight from above) and thrust loads (sideways force). However, perfectly round ball bearings have a very small contact area. This limits them to light-to-medium applications and to locations on a vehicle that are not subject to heavy pressure and shocks from road impacts.

Ball bearings – These are perfectly round metal balls. While they’re used in some automotive bearing assemblies, they are more commonly found in skateboards, electric motors, and household machinery. Because their spherical shape allows them to spin in any direction, they can handle both radial loads (weight from above) and thrust loads (sideways force). However, perfectly round ball bearings have a very small contact area. This limits them to light-to-medium applications and to locations on a vehicle that are not subject to heavy pressure and shocks from road impacts.

Straight roller bearings – These are cylindrically shaped, round, and have a constant diameter straight across their entire length – similar to a log. Because radial loads placed on them are spread out evenly across a much wider contact point, they are good for some heavier-duty applications. The drawback of straight roller bearings is that their shape does not allow them to handle significant thrust loads. Bearing assemblies with smaller-diameter straight roller bearings are often used in tight spaces such as gear boxes.

Straight roller bearings – These are cylindrically shaped, round, and have a constant diameter straight across their entire length – similar to a log. Because radial loads placed on them are spread out evenly across a much wider contact point, they are good for some heavier-duty applications. The drawback of straight roller bearings is that their shape does not allow them to handle significant thrust loads. Bearing assemblies with smaller-diameter straight roller bearings are often used in tight spaces such as gear boxes.

Tapered roller bearings – These are wider the way roller bearings are with a slight taper on ones side. They’re placed inside bearing assemblies with a larger amount of taper because physics allows this shape to handle heavy amounts of radial pressure, thrust loads, and hard shocks. Tapered bearings are most often used in wheel bearing assemblies mounted inside of wheel hubs. Some automakers use one bearing assembly with tapered roller bearings and others pair these assemblies up next to each other, facing in opposite directions.

Tapered roller bearings – These are wider the way roller bearings are with a slight taper on ones side. They’re placed inside bearing assemblies with a larger amount of taper because physics allows this shape to handle heavy amounts of radial pressure, thrust loads, and hard shocks. Tapered bearings are most often used in wheel bearing assemblies mounted inside of wheel hubs. Some automakers use one bearing assembly with tapered roller bearings and others pair these assemblies up next to each other, facing in opposite directions.

OTHER COMPONENTS RELATED TO A BEARING ASSEMBLY

Race – This is a metal ring with smooth, machined inner and outer surfaces. Bearings are surrounded by a race which provides the outer surface against which they rotate. Races are often included with a new bearing assembly, but check to make sure you know what you’re getting before making a purchase. If a new race is not included with bearings, it should be purchased separately and replaced as well, because an old race should never be re-used – no matter good its condition may appear to the naked eye.

Race – This is a metal ring with smooth, machined inner and outer surfaces. Bearings are surrounded by a race which provides the outer surface against which they rotate. Races are often included with a new bearing assembly, but check to make sure you know what you’re getting before making a purchase. If a new race is not included with bearings, it should be purchased separately and replaced as well, because an old race should never be re-used – no matter good its condition may appear to the naked eye.

Bearing cage – A special form of race specially perforated to cradle the bearings themselves. The bearing cage provides the inner surface against which bearings rotate. Bearing cages are not usually sold separately because they are typically part of a bearing assembly.

Bearing cage – A special form of race specially perforated to cradle the bearings themselves. The bearing cage provides the inner surface against which bearings rotate. Bearing cages are not usually sold separately because they are typically part of a bearing assembly.

Bearing seal – An O-shaped round seal (usually hardened rubber) used to surround part of a bearing assembly so grease doesn’t leak out. Bearing seals are a wear item, and must always be replaced with bearings. If the bearing assembly for your vehicle does not come with a built-in seal, bearing seals are usually sold individually.

Bearing seal – An O-shaped round seal (usually hardened rubber) used to surround part of a bearing assembly so grease doesn’t leak out. Bearing seals are a wear item, and must always be replaced with bearings. If the bearing assembly for your vehicle does not come with a built-in seal, bearing seals are usually sold individually.

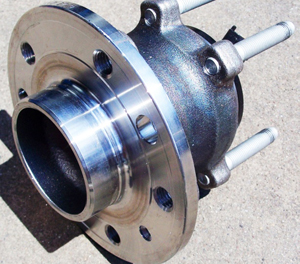

Wheel hub – A forged or cast piece of metal that an automobile wheel mounts to. Wheel bearing assemblies typically fit inside the center of the wheel hub to allow free rotation around an axle shaft or spindle. Bearing assemblies that mount inside a wheel hub are often called wheel hub bearing assemblies. Depending on vehicle manufacturer, some wheel hub bearing assemblies are constructed with integral bearing assemblies which cannot be replaced separately. Instead, the wheel hub must be replaced as a whole.

Wheel hub – A forged or cast piece of metal that an automobile wheel mounts to. Wheel bearing assemblies typically fit inside the center of the wheel hub to allow free rotation around an axle shaft or spindle. Bearing assemblies that mount inside a wheel hub are often called wheel hub bearing assemblies. Depending on vehicle manufacturer, some wheel hub bearing assemblies are constructed with integral bearing assemblies which cannot be replaced separately. Instead, the wheel hub must be replaced as a whole.

Bearing grease – This is a heavy-duty petroleum-based or synthetic grease designed to provide lubrication of high-friction surfaces. Unlike gear oil or motor oil, bearing grease remains thick and sticky at high temperatures because of its heavy viscosity, and will not run off surfaces the way thinner fluids do. Having clean grease on hand is essential when doing any repair work involving bearings or related parts. Grease in a container that’s been left open to the air for a period of time tends to draw airborne dust and dirt like a magnet, so if you find the lid of your container was not on tight or has become compromised, your grease has too. Replace it with a new container.

Bearing grease – This is a heavy-duty petroleum-based or synthetic grease designed to provide lubrication of high-friction surfaces. Unlike gear oil or motor oil, bearing grease remains thick and sticky at high temperatures because of its heavy viscosity, and will not run off surfaces the way thinner fluids do. Having clean grease on hand is essential when doing any repair work involving bearings or related parts. Grease in a container that’s been left open to the air for a period of time tends to draw airborne dust and dirt like a magnet, so if you find the lid of your container was not on tight or has become compromised, your grease has too. Replace it with a new container.

Bearing grease packer – A specially shaped receptacle approximately the size of a large coffee mug with a center shaft. A grease packer allows you to drop an entire O-shaped bearing assembly inside of it where it will sit atop lubricating grease inside the packer. The top part of the grease packing tool is then inserted. With downward pressure applied, the bearing assembly becomes immersed into the thick grease which squeezes into all gaps between the bearings, cage, and race. This is the easiest and most efficient way to get grease inside most of the bearing areas. After removing your bearing assembly from a grease packer, it’s also a good idea to apply a final coating of grease by hand around the outer circumference of the bearing assembly.

Bearing grease packer – A specially shaped receptacle approximately the size of a large coffee mug with a center shaft. A grease packer allows you to drop an entire O-shaped bearing assembly inside of it where it will sit atop lubricating grease inside the packer. The top part of the grease packing tool is then inserted. With downward pressure applied, the bearing assembly becomes immersed into the thick grease which squeezes into all gaps between the bearings, cage, and race. This is the easiest and most efficient way to get grease inside most of the bearing areas. After removing your bearing assembly from a grease packer, it’s also a good idea to apply a final coating of grease by hand around the outer circumference of the bearing assembly.

FRONT-, REAR-, and ALL-WHEEL-DRIVE VEHICLES

Bearing terminology gets a little trickier when differences for front-, rear-, and all-wheel-drive vehicles are factored in. Things also vary depending on which wheels are drive wheels and which are not. For example, bearings for drive wheels are known as “axle bearings” whether they’re front or rear because those wheels are mounted to the hub of an axle shaft which rotates within a housing. Bearing assemblies on front or rear non-driven axles are correctly termed “wheel bearings”, and they mount between a wheel hub and a simple spindle shaft. An all-wheel-drive vehicle would have four axle bearings. Regardless of these differences, most axle and wheel bearing assemblies are blanketed under the term “wheel bearings” – something to consider when looking for replacement parts.

TYPES OF BEARING DESIGNS USED ON FRONT WHEEL HUBS

Shown in this picture is a replaceable grease seal that is not part of a wheel hub bearing assembly.

Usually, a pair of tapered style bearing assemblies next to each other are used for front-wheel-drive hubs because vehicle weight is distributed more heavily up front, and lateral forces generated as wheels turn can be severe. In some cases, bearing assemblies for front-wheel-drive hubs are sealed units that never need lubrication. Others are designed to be serviced and feature a replaceable grease seal that’s changed each time bearings are repacked with grease.

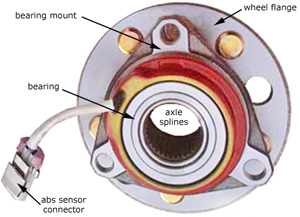

This picture of a recent General Motors integrated wheel hub is typical of how most modern vehicles design a hub, bearing assembly, mounting, and wheel flange into an integrated unit for the front wheels.

On older vehicles, front wheel bearings were designed to be serviced with repair kits because parts can be individually disassembled, cleaned, and re-packed with grease. Newer vehicles are typically equipped with assemblies for front wheels that include hub, bearing assembly, mounting, and wheel flange integrated into one unit. Depending on the vehicle manufacturer’s preference, some bearing assemblies are pressed into the knuckle and can’t be replaced without special tools. While most integrated wheel hub bearing assemblies cost more, they are easier to replace using standard wrenches.

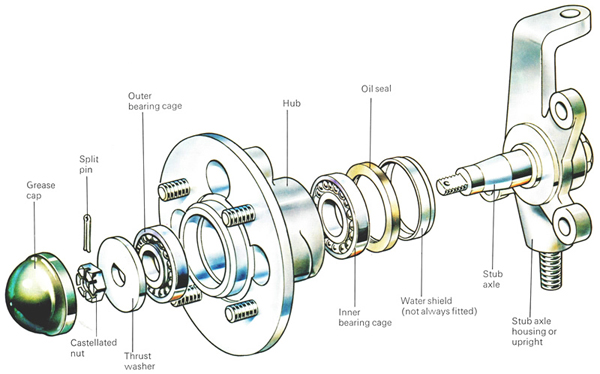

This exploded drawing shows an older style wheel bearing setup where all parts at the hub can be taken apart, cleaned, and replaced more easily.

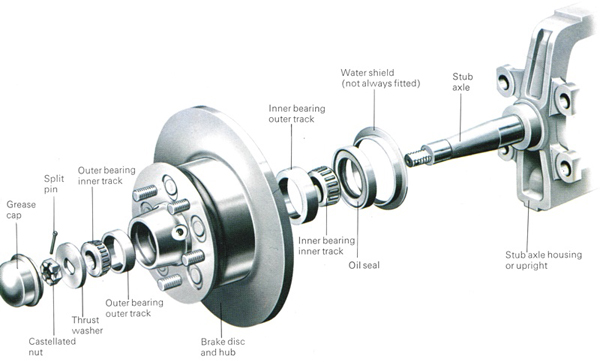

This exploded drawing shows an older style wheel bearing setup where a wheel hub is bolted to a disc brake rotor. Individual parts here can also be taken apart, cleaned, and replaced more easily.

TYPES OF BEARING DESIGNS USED ON REAR WHEEL HUBS

Many rear-wheel-drive bearings on rear hubs of vehicles with solid beam rear axles are actually of the straight roller bearing type design – sometimes with dual rows of bearings. In other cases, the axle tubes are even set up to double as races for those bearings. Vehicles with independent rear suspension layouts and non-driven rear hubs on front-wheel-drive vehicles will usually feature tapered roller bearing type assemblies, or even ball bearing assemblies.

Many rear-wheel-drive bearings on rear hubs of vehicles with solid beam rear axles are actually of the straight roller bearing type design – sometimes with dual rows of bearings. In other cases, the axle tubes are even set up to double as races for those bearings. Vehicles with independent rear suspension layouts and non-driven rear hubs on front-wheel-drive vehicles will usually feature tapered roller bearing type assemblies, or even ball bearing assemblies.

AXLE SHAFT BEARINGS

Axle shaft bearings are mounted at inboard locations and support the weight of the vehicle while keeping a drive axle centered in place as it rotates. Ball-type bearings, straight roller bearings, and tapered type roller bearings are all used in these axle shaft bearing assemblies, and they vary depending on manufacturer preference. Most ball bearings and tapered bearings are held in place by a bearing outer retainer, while axles with straight-roller bearings use a C-shaped clip located inside the rear differential.

Axle shaft bearings are mounted at inboard locations and support the weight of the vehicle while keeping a drive axle centered in place as it rotates. Ball-type bearings, straight roller bearings, and tapered type roller bearings are all used in these axle shaft bearing assemblies, and they vary depending on manufacturer preference. Most ball bearings and tapered bearings are held in place by a bearing outer retainer, while axles with straight-roller bearings use a C-shaped clip located inside the rear differential.

Ball-type axle bearing assemblies are pressed on and off the axle shaft, and a retainer ring made of soft metal is pressed onto the shaft against the wheel bearing. Roller axle bearings are lubricated by gear oil inside the differential housing, and are most often pressed into that housing rather than onto the axle. Tapered roller axle bearings are sealed with typical axle grease for lubrication, and must be pressed on or off the axle shaft.

Ball-type axle bearing assemblies are pressed on and off the axle shaft, and a retainer ring made of soft metal is pressed onto the shaft against the wheel bearing. Roller axle bearings are lubricated by gear oil inside the differential housing, and are most often pressed into that housing rather than onto the axle. Tapered roller axle bearings are sealed with typical axle grease for lubrication, and must be pressed on or off the axle shaft.

When it comes time to replace any bearing components, the “type” of bearings or bearing assemblies you need are determined strictly by how your exact vehicle was engineered from the beginning. Getting the right parts to match what’s on your vehicle will save you frustration and wasted time when things don’t fit. It will spare you from wasting money when wrong parts installed have become damaged and need to be replaced again, along with other related components that might have become damaged as a result.