Alternators and starter motors have a tough job. Alternators are in motion every minute the engine is running, and they must be producing electricity at peak efficiency for all vehicle systems to function. Starter motors must use electricity supplied to them effectively enough to turn over an entire engine with the speed it needs to catch.

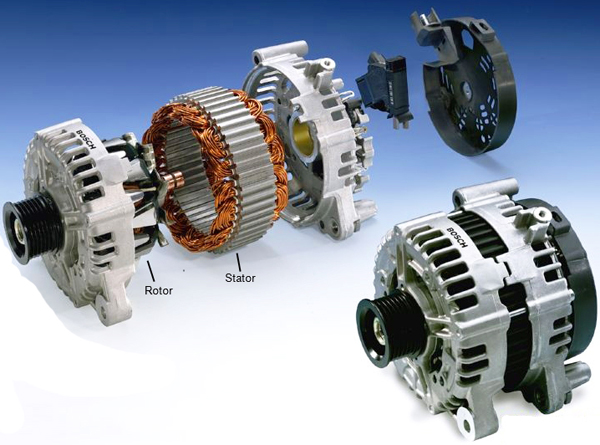

These hard-working parts consist of diodes, stators, brushes, magnetic switches, and other components that are the core of electric power. Over time those components are prone to corrosion and wear, ultimately needing replacement no matter how a vehicle is driven.

In this article, we’ll discuss both new and re-manufactured replacement starters and alternators. There are pros and cons purchasing each choice, but one fact is universal – if the alternator or starter you install isn’t up to the standards your vehicle was built on, neither part will survive for long.

REMANUFACTURED PARTS

When looking at parts that aren’t new, you’ll come across the terms “remanufactured” and “rebuilt”. They are not the same thing, and it’s important to know the difference before buying anything classified with either designation. A remanufactured part is one that has undergone a major teardown and has had all wear and moving parts replaced with new ones, regardless of condition. Depending on the application, some re-machining may be done also. Because each and every component is replaced automatically, it’s pretty much a guarantee that mechanical tolerances are restored to OEM new-part standards. Additionally, re-manufactured parts often distinguish themselves by mirroring updates and improvements the OEM manufacturer has made to earlier originals. High-quality remanufacturers will test each individual component they use before re-assembly, then they’ll test the final product once it’s been assembled.

When looking at parts that aren’t new, you’ll come across the terms “remanufactured” and “rebuilt”. They are not the same thing, and it’s important to know the difference before buying anything classified with either designation. A remanufactured part is one that has undergone a major teardown and has had all wear and moving parts replaced with new ones, regardless of condition. Depending on the application, some re-machining may be done also. Because each and every component is replaced automatically, it’s pretty much a guarantee that mechanical tolerances are restored to OEM new-part standards. Additionally, re-manufactured parts often distinguish themselves by mirroring updates and improvements the OEM manufacturer has made to earlier originals. High-quality remanufacturers will test each individual component they use before re-assembly, then they’ll test the final product once it’s been assembled.

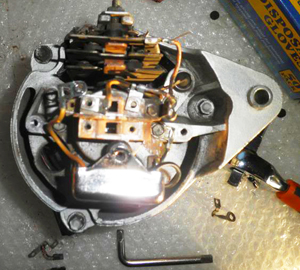

A rebuilt part differs because when the original is torn apart, only those components that are majorly worn or broken get replaced. Other bits that appear to still be functional are merely cleaned and re-used. Rebuilt parts can vary in quality, and they usually cannot match the performance or longevity of a new or remanufactured one. Final results often come down to the ethics of the person or company doing the rebuilding more than anything else and the internet is full of stories of “rebuilt” starters and alternators with rusty, old internals still in place hidden by a new-looking respray on the outer housing.

A rebuilt part differs because when the original is torn apart, only those components that are majorly worn or broken get replaced. Other bits that appear to still be functional are merely cleaned and re-used. Rebuilt parts can vary in quality, and they usually cannot match the performance or longevity of a new or remanufactured one. Final results often come down to the ethics of the person or company doing the rebuilding more than anything else and the internet is full of stories of “rebuilt” starters and alternators with rusty, old internals still in place hidden by a new-looking respray on the outer housing.

Remanufacturers tend to offer better warranties than what you’ll typically find on rebuilt parts, so choosing remanufactured part over a rebuilt one is the logical choice. As a side note, a part from a different country sold here as “rebuilt” might actually be new because rebuilt parts carry a lower import tariff. Instead of using different part numbers that would raise suspicion, new items are brought in under the “rebuilt” part number. However, this is less common and there’s no way to anticipate what you’ll get without a visual inspection.

NEW PARTS

If you’ve decided your preference is buying new parts, there’s the further question of dealer vs. aftermarket (pros and cons of both are covered in another article on our website). Looking for parts from major aftermarket manufacturers will usually always yield good results – especially if it’s a company that was outsourced to build the parts originally installed on your vehicle during its trip down the assembly line. “OE” (original equipment) parts that match the original vehicle manufacturer’s specifications means the parts would be able to clear the same reliability tests used for acceptance by the vehicle manufacturer.

Quality can vary on new aftermarket parts, so it’s a good idea to get opinions from those who have come in contact with them. Automotive forum pages are a great source of information when it comes to experiences do-it-yourselfers have had. If you know a mechanic you trust, ask their opinions because they are certain to have dealt with plenty of good and bad parts. Usually big name companies care about quality/reputation, therefore their rebuilt parts are high quality. While it’s not advisable to purchase “low quality” new parts, there’s no need to buy the best, most expensive ones either if you foresee selling, trading, or junking your vehicle in the near future.

CORE CHARGES

Whether you buy a brand-new part or a remanufactured one, you may see a “core charge” listed in many cases. A core charge is a credit given back to you for returning an old part after receiving your new one, because the “core” of the old part still has value. The company you dealt with will use the shell and other assorted components to remanufacture your old part for the next customer.

Whether you buy a brand-new part or a remanufactured one, you may see a “core charge” listed in many cases. A core charge is a credit given back to you for returning an old part after receiving your new one, because the “core” of the old part still has value. The company you dealt with will use the shell and other assorted components to remanufacture your old part for the next customer.

Usually, full purchase price is paid for the replacement part then the core charge is given to you as a credit after the retailer receives your used part. One detail to look for is who pays the cost of shipping your old starter or alternator back. If the company you’re purchasing from doesn’t specify it, call them and ask. Paying the freight on a heavy alternator or starter can easily offset credit you’ll get for returning it.

ALTERNATORS

For example, Bosch makes the claim with their remanufactured alternators that a superior voltage regulator circuit design maintains optimal voltages during all conditions to maximize the charging of the battery, and that digitally tested rotors ensure up to 20% increased performance when it comes to maintaining a full battery charge. Longer lasting bearings are constructed using the latest advances in precision grinding, polishing, and lubrication technologies to provide up to a 30% increased life over conventional bearings