Wheels that catch your eye because they really set off a vehicle do so because they are clean and sparkling, not dirty. If turning back to gaze at your own rims brings disappointment, the time is now to clean them up, get them looking their best with a shine, and develop a routine for keeping them that way. A car with clean, good-looking rims always commands a higher sale price, so preventing your wheels from getting tarnished just makes economic sense. In this article, we’ll cover the types of wheel finishes and wheel care cleaners best suited to them.

Wheels that catch your eye because they really set off a vehicle do so because they are clean and sparkling, not dirty. If turning back to gaze at your own rims brings disappointment, the time is now to clean them up, get them looking their best with a shine, and develop a routine for keeping them that way. A car with clean, good-looking rims always commands a higher sale price, so preventing your wheels from getting tarnished just makes economic sense. In this article, we’ll cover the types of wheel finishes and wheel care cleaners best suited to them.

Whether you’ve spent big money on custom rims or just want to maintain the beauty of your original factory wheels, the right cleaners and polishes will quickly and effectively soften and remove brake dust, stains from oily road debris, and other airborne pollutants. For bringing out the mirror shine of chrome wheels, chrome wheel polish comes in a thick cream that softens and removes tarnishing and spotting while it brightens surfaces. Ingredients seal out moisture to prevent the pitting, corrosion, and peeling that can plague chrome when left unprotected to the elements. And if you’ve got polished or machined aluminum wheels that aren’t painted, aluminum polish is strong enough to work over even the most neglected of metals, yet gentle enough to use regularly. With proper protection, wheel surfaces will have a finish that’s resistant to oily deposits, fingerprints, streaks, and smearing.

When washing your wheels, it’s best to go with the basics. Use mild soap and water only, and avoid applying cold water to wheels that have become heated from use or from being in the sun. Let them cool down naturally first, otherwise the rapid temperature change can “shock” an outer layer of clear coat finish – resulting in hairline cracks and pits forming in it. As dirt and moisture work their way underneath the clear coat and become trapped there, premature stains form along with peeling that looks terrible to the eye.

After the wheels have been cleaned, caked-on grime can be removed along with stains and pitting on the top surface using wheel cleaners designed for the finish on your wheels. Then move on to applying polishing compounds with a simple high-speed buffer that generates heat friction to get the most effective results. If any bumpy or gritty residue remains, use a non-abrasive clay bar to remove any hardened tar, tree sap, and gunk. If you don’t own a high-speed buffer or find it awkward to use on wheels, a large rotating foam ball, small rotating foam ball, or foam cone attached to a common electric drill will net equally effective results.

Wash the wheels every two weeks during warmer months with a soft scrubbing brush – weekly if they come in contact with road salt or high levels of oil-based contaminants. Apply a layer of car wax or acid-free grease such as Vaseline every few months with a soft cloth then buff it off. This will allow brake dust and gunk slide off wheel surfaces instead of building up a gooey layer which, if left unchecked, bakes into a hard coating that’s difficult to remove.

If you work on your wheels after cleaning the rest of your vehicle, keep a bottle of automotive paint cleaner handy to wipe up any overspray from wheel cleaners or polishes that get on your paint.

PAINTED WHEELS WITH CLEAR COAT FINISH

Clear coat is often applied as the final layer on aluminum wheels that have been painted with gloss paint of any color, and it’s often used on machined aluminum wheels as well. The clear coat layer consists of a urethane film with an adhesive backing and hardens to a thickness typically less than 1/100th of an inch. It has no color, and is designed to be scratch resistant to prevent dulling of colored paint layers underneath it.

Clear coat is often applied as the final layer on aluminum wheels that have been painted with gloss paint of any color, and it’s often used on machined aluminum wheels as well. The clear coat layer consists of a urethane film with an adhesive backing and hardens to a thickness typically less than 1/100th of an inch. It has no color, and is designed to be scratch resistant to prevent dulling of colored paint layers underneath it.

Clean wheels with clear coat in a traditional fashion using a safe, recommended wheel cleaner to lift and separate brake dust and grease during washing.

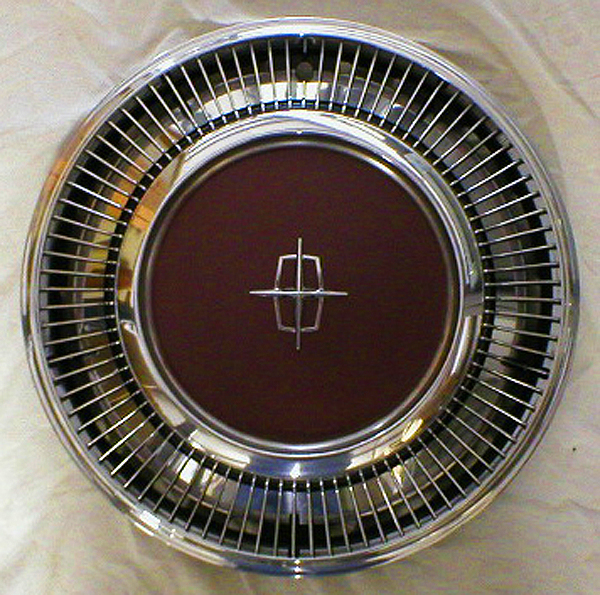

WHEELS WITH CHROME FINISH:

Before chromium is applied to an aluminum wheel, alloy coatings such as nickel, copper, or zinc are sprayed on first. As an element, aluminum has a natural tendency to clash chemically with chromium, so chrome-coated aluminum wheels need to be kept extremely clean to minimize this. Road salt and other contaminants will do more than tarnish and pit the outside surface – they’ll cause the chrome finish to bubble and peel off from the inside out. Wheel industry experts highly recommend NOT using chromed wheels in winter when roads are salty and slushy.

Before chromium is applied to an aluminum wheel, alloy coatings such as nickel, copper, or zinc are sprayed on first. As an element, aluminum has a natural tendency to clash chemically with chromium, so chrome-coated aluminum wheels need to be kept extremely clean to minimize this. Road salt and other contaminants will do more than tarnish and pit the outside surface – they’ll cause the chrome finish to bubble and peel off from the inside out. Wheel industry experts highly recommend NOT using chromed wheels in winter when roads are salty and slushy.

Use specially formulated chrome wheel cleaner because it will have a natural formula based on citrus oils with enough acidic pH balance to lift dirt and grime off the surface. This type of wheel cleaner is also formulated to counteract chrome’s natural tendency to repel water and other liquids to work effectively. Chrome wheel cleaner is not designed for use on bare aluminum surfaces such as polished or machined wheels.

WHEELS WITH MACHINED FINISH

Machined is the term used to describe what happens to an aluminum wheel during manufacturing after its last shaping procedure on a lathe. The wheel is passed through successively finer cutting and polishing processes until very fine circular ridges are etched in the wheel face and the aluminum glows with a subtle sheen. Machined wheels are not painted but a clear coat layer is most often applied on top of the machined surface.

Machined is the term used to describe what happens to an aluminum wheel during manufacturing after its last shaping procedure on a lathe. The wheel is passed through successively finer cutting and polishing processes until very fine circular ridges are etched in the wheel face and the aluminum glows with a subtle sheen. Machined wheels are not painted but a clear coat layer is most often applied on top of the machined surface.

Using steel wool pads or anything overly abrasive can literally sand down the etched texture on these wheels, so it’s recommended to clean and buff with soft terrycloth hand towels or orbital buffing balls (see reference at beginning of article).

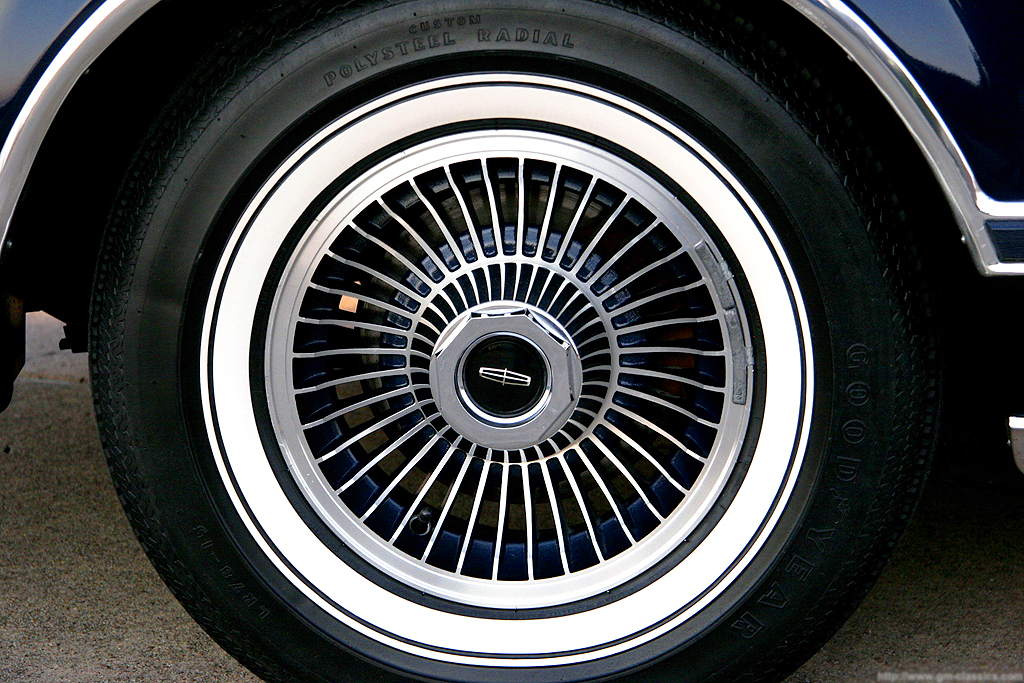

WHEELS WITH A POLISHED ALUMINUM FINISH

Aluminum wheels with a polished finish are not painted, and machine polishing during the manufacturing process brings out the natural beauty of the aluminum underneath. Their high shine is not unlike the dazzling effect of chrome, and a layer of clear coat is often applied on top to prevent metal deterioration. If a clear coat isn’t used, this type of wheel will need re-polishing on a regular basis to maintain their high shine. This type of wheel is more time-consuming to maintain, but surface scratches and stains can be removed with high-speed buffing/polishing tools easier. Properly cared for, they’ll remain durable through all seasons and winter weather.

Aluminum wheels with a polished finish are not painted, and machine polishing during the manufacturing process brings out the natural beauty of the aluminum underneath. Their high shine is not unlike the dazzling effect of chrome, and a layer of clear coat is often applied on top to prevent metal deterioration. If a clear coat isn’t used, this type of wheel will need re-polishing on a regular basis to maintain their high shine. This type of wheel is more time-consuming to maintain, but surface scratches and stains can be removed with high-speed buffing/polishing tools easier. Properly cared for, they’ll remain durable through all seasons and winter weather.

Polished aluminum wheels should never be used with chrome cleaners or polish, because chemical agents designed for chromium tend to leave permanent stains on the aluminum which can’t be removed. Instead, use a specialized polished aluminum wheel cleaner that contains only solvents without abrasives. A good cleaning solution of this type will soften and lift caked-on brake dust, hardened road tar, and other grime within minutes to be rinsed away. Polished aluminum wheel cleaner can also be used effectively on any painted, powder coated, chromed, and clear coated wheel surfaces.

Aluminum wheel polish works well because it has been carefully refined and blended with compounds necessary for effective renewal of metal surfaces. First, abrasives scour and remove microscopic peaks which appear as a dull patina on metal. Then, solvents effectively clean grime, oxidation, and road tars away. Sealants in the paste seal the metal and protect it against oxidation. While this polish is designed primarily for polishing aluminum wheels, it effectively scours haze and discoloration off plastic headlight and taillight lens assemblies that builds up naturally from acid rain and other airborne contaminants.

WHEELS WITH MATTE FINISH

A matte finish is generated by using paint that dries with a rough surface full of imperfections and dimples that diffuse light rays, making the wheel surface appear non-reflective to the eye. Traditional wheel polishing and wax compounds should never be used with matte wheels, because they will literally fill those imperfections and create a shine – reversing the matte effect.

A matte finish is generated by using paint that dries with a rough surface full of imperfections and dimples that diffuse light rays, making the wheel surface appear non-reflective to the eye. Traditional wheel polishing and wax compounds should never be used with matte wheels, because they will literally fill those imperfections and create a shine – reversing the matte effect.

Clean any brake dust or road grime off wheel surfaces as soon as possible with clean water and a microfiber towel. Avoid use of synthetic cloths, and use wheel cleaner specially formulated for matte finish wheels. Using matte paint sealant without silicons or fillers right after washing the surface is ideal because this provides molecular protection for months. Matte finish wheel cleaner is also excellent for powder coated wheel surfaces as well.